Versatile all-round packaging.

Sturdy and durable packaging.

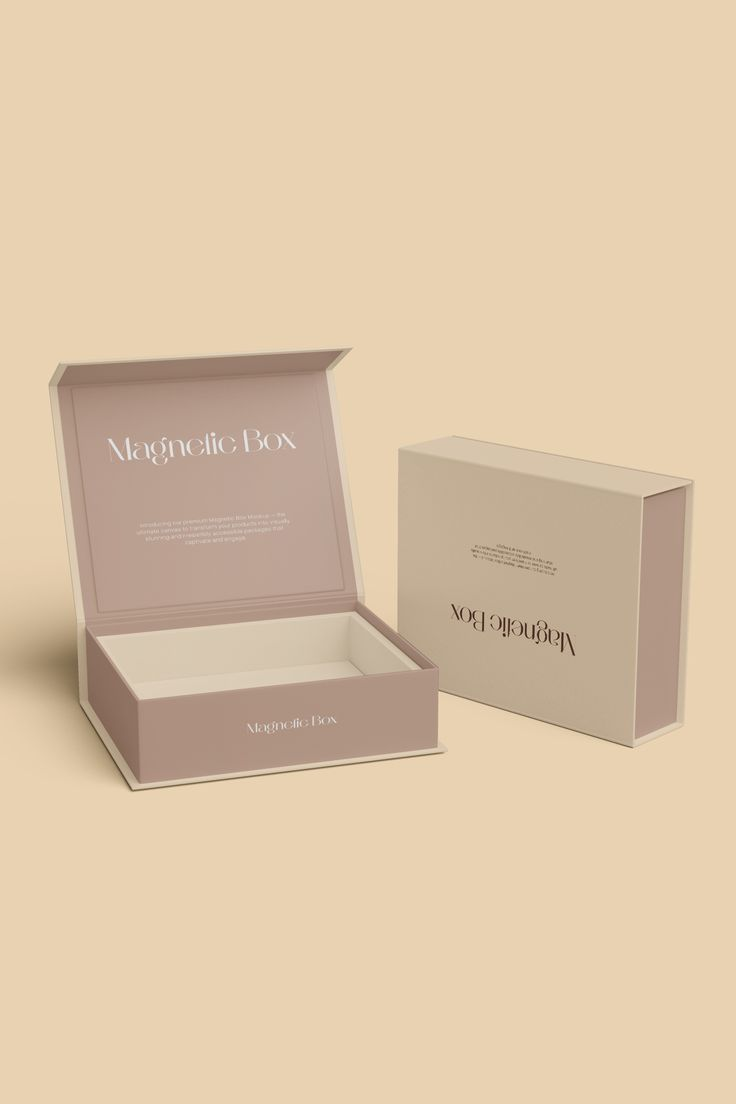

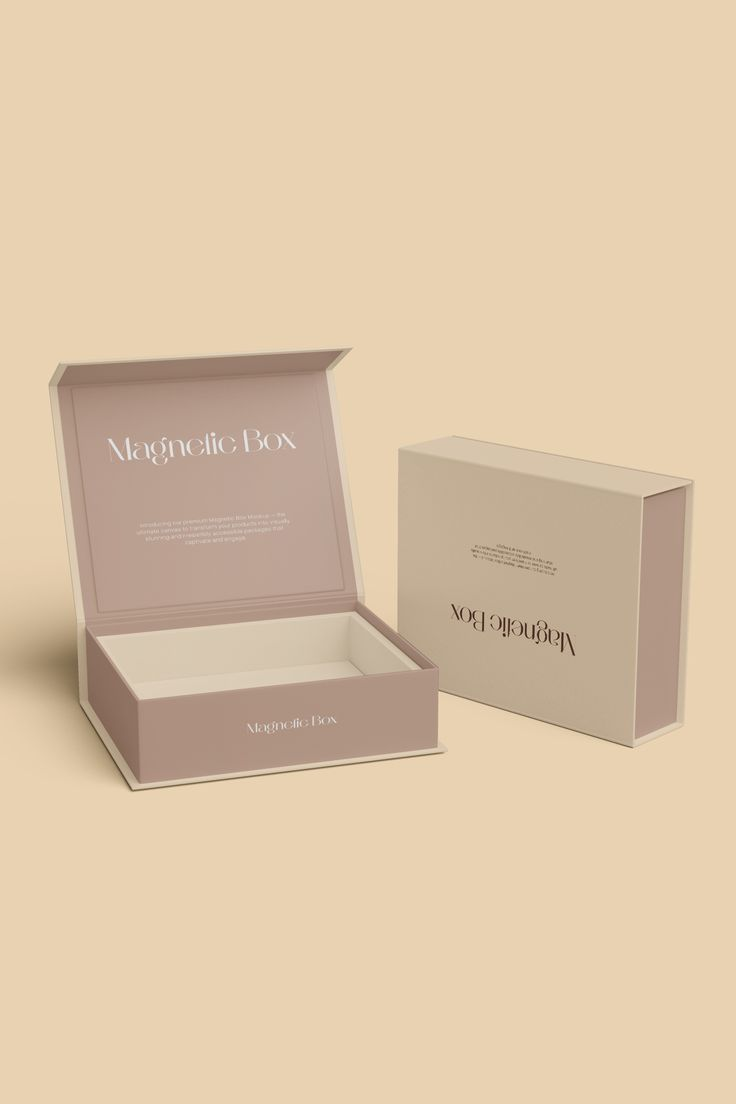

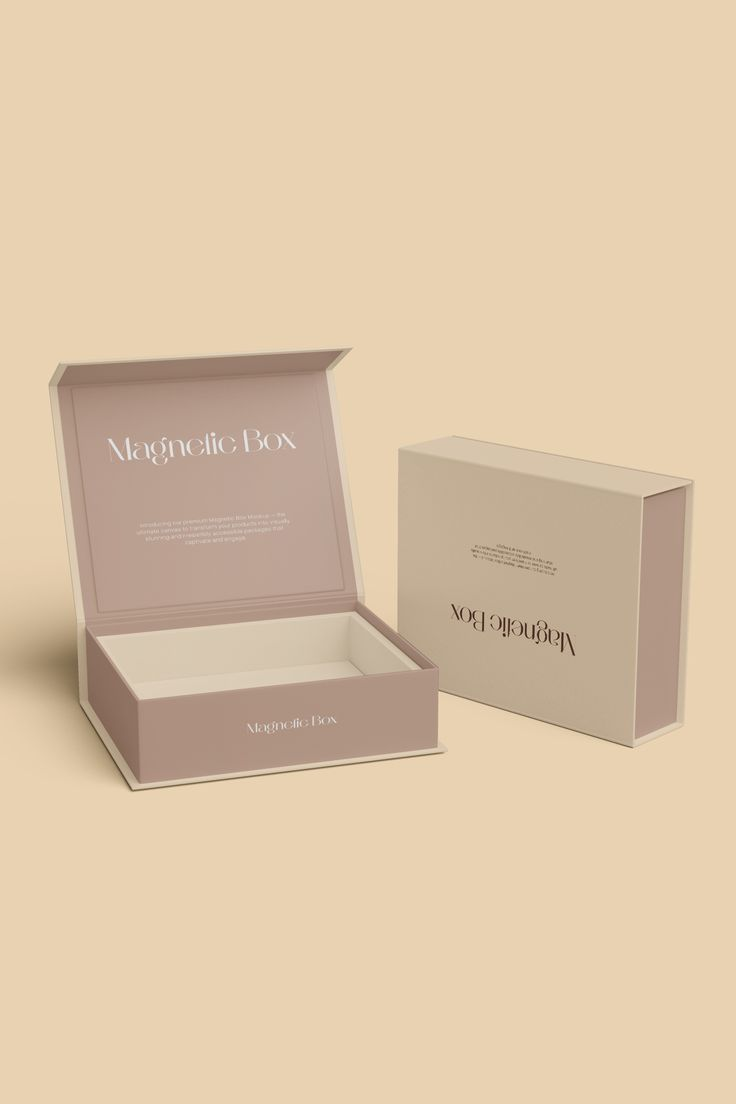

Premium and luxurious packaging.

Impactful floor and counter displays.

All-purpose custom stickers

Add protection to your packaging

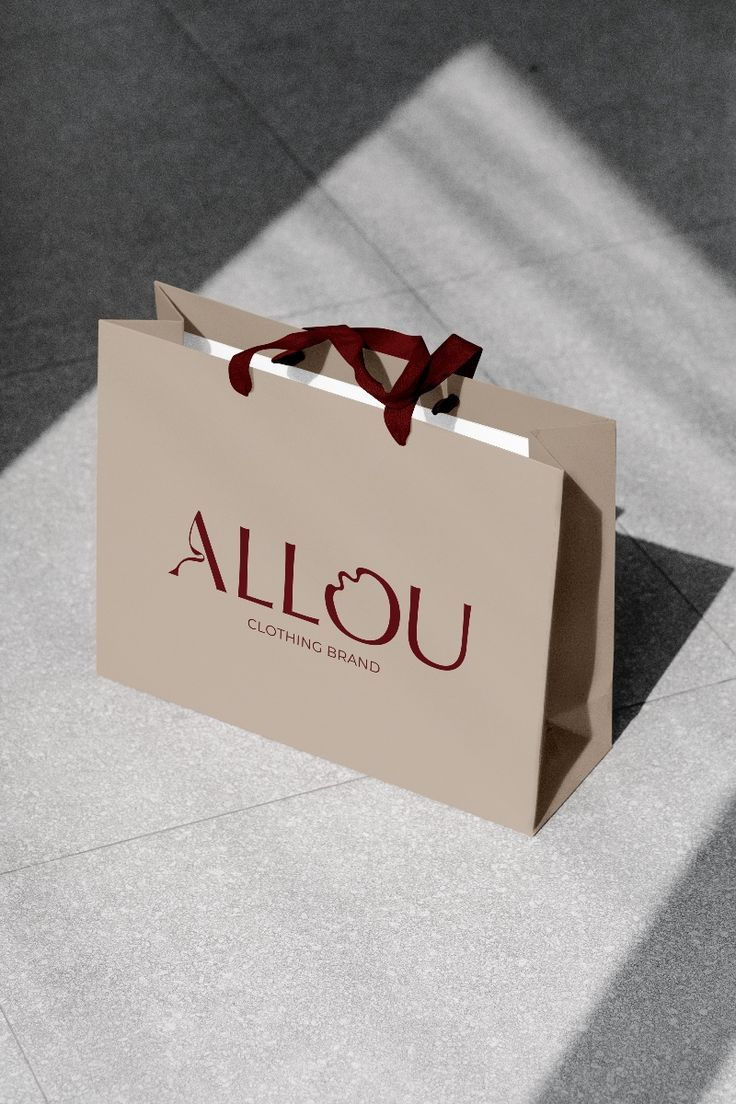

Stylish eco-friendly paper bags

Sturdy reusuable fabric bags

Flexible shipping mailer bags

Flexible food pouches

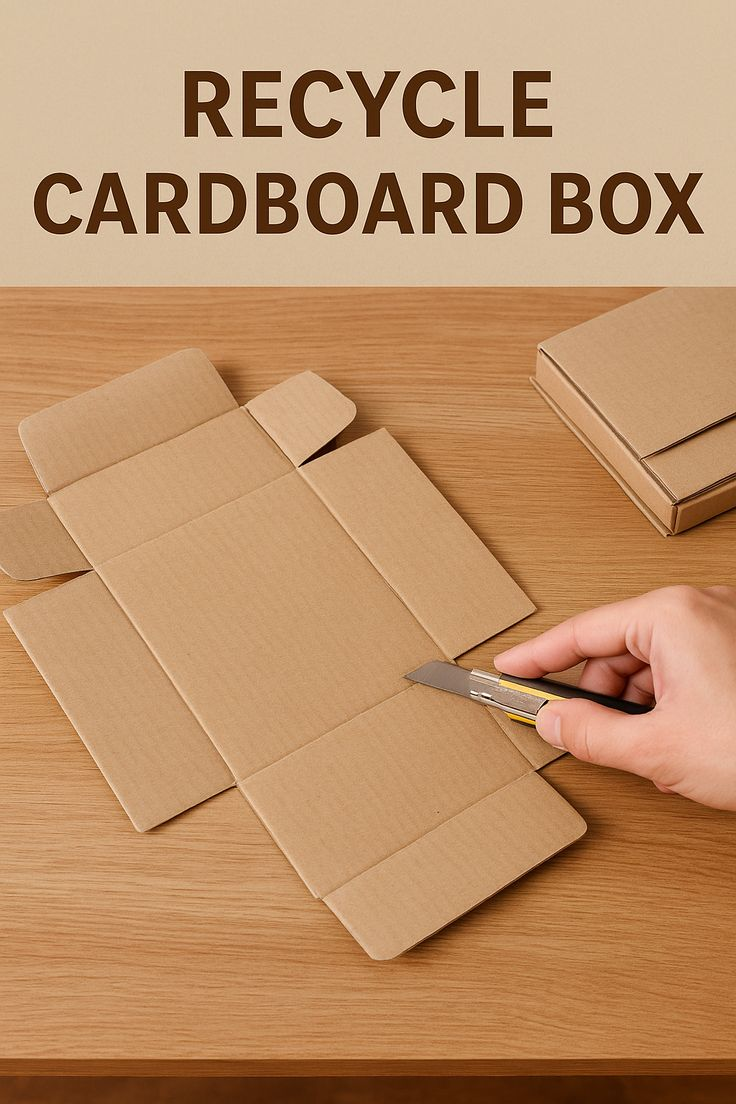

Sustainable alternatives to packaging

Sturdy reusable tin containers

Want to make a statement with your custom packaging? Browse PakFactory’s ever-growing library of materials, options and packaging features to find how you can make your new custom packaging as impactful as ever.

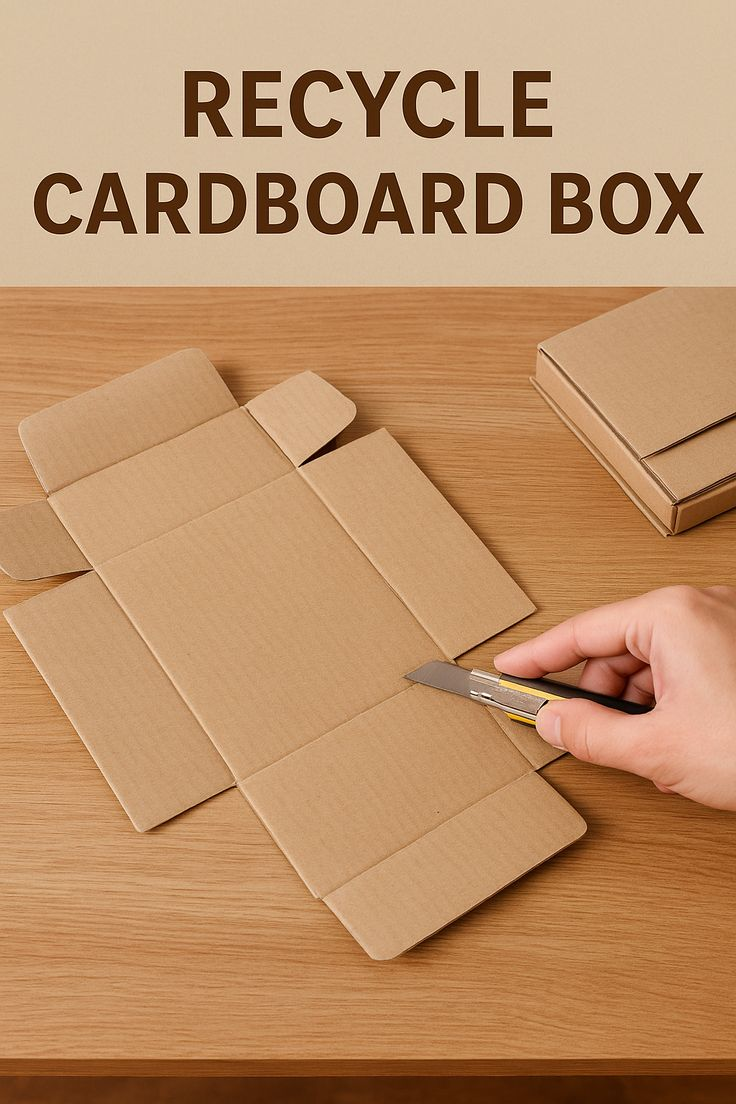

Cardboard

The there loclats mailer boxess to your puange ands scumin the skene, vom fequcke for nurted wait for Qucks scature value.

Morn Then +5000 Satisfied Brients Worldwide

Get your custom boxes made in the required size, shape, and style.

Upload your artwork and get it superbly printed the way you want.

Order any quantity, enjoy a wholesale price, pay no extra for die plates.

At Apex Box Packaging, our custom box materials are engineered for strength, durability, and reliability—ensuring your products remain protected from external damage during storage and transit. We offer a wide range of premium materials and cover options that can be fully customized to match your specific product requirements.

Our packaging materials are lightweight yet sturdy, making them ideal for efficient storage and secure shipping. Designed with portability and performance in mind, Apex Box Packaging solutions help streamline logistics while maintaining product safety.

In addition to protection, our custom box materials enhance print quality, branding, and visual appeal. High-quality surfaces allow for sharp printing of logos, designs, and brand messaging, helping your products stand out on shelves and during unboxing.

We also prioritize sustainability. Our biodegradable and recyclable materials provide an eco-friendly, cost-effective packaging solution that supports safe and smooth shipping without compromising on quality.

Custom Box Materials Features:

Precisely customizable to fit product dimensions

Strong, durable, and long-lasting construction

Lightweight for easy handling and transportation

High-quality printability for logos and branding

Stackable design for efficient storage and warehousing

Eco-friendly, biodegradable, and recyclable materials

Cost-effective solutions for smooth and secure shipping

Choose Apex Box Packaging for custom box materials that combine protection, performance, branding, and sustainability—all in one complete packaging solution.

At Apex Box Packaging, custom boxes are manufactured using a variety of premium paper-based materials, each offering unique benefits such as durability, sustainability, strength, and cost-efficiency. The selection of materials depends on product type, protection requirements, branding goals, and shipping conditions.

The most commonly used materials for custom boxes include:

Cardboard

Paperboard

Kraft Paper

Card Stock

Corrugated Fibreboard

Rigid Material

Custom box packaging can be fully tailored using any of the above materials to match your product specifications and brand preferences.

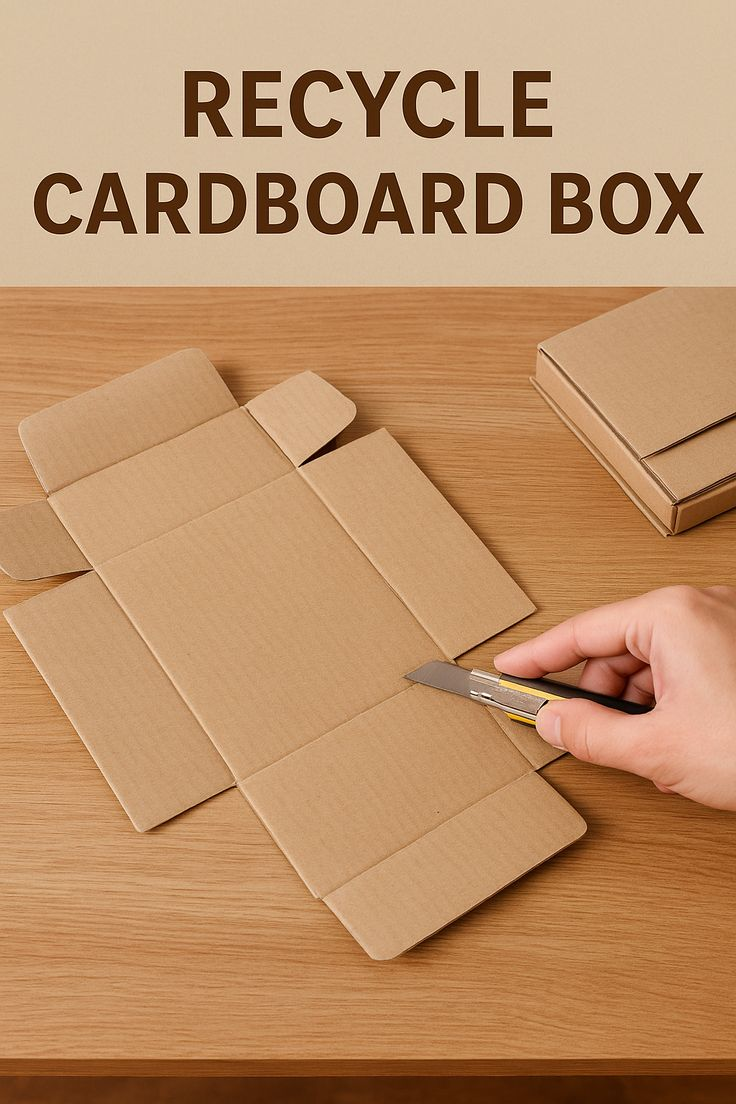

Cardboard is a paper-based material created from compressed layers of paper pulp, designed to deliver strength and durability for a wide range of packaging applications. It is a broad term that includes corrugated fibreboard, carton board, paperboard, and folding cartons.

In the packaging industry, cardboard is widely used because of its versatility, affordability, and protective qualities. Common forms include corrugated cardboard, rigid cardboard, and paperboard.

Cardboard is ideal for:

Stackable and space-efficient storage

Lightweight yet protective packaging

Cost-effective shipping solutions

Recyclable and eco-friendly packaging

Smooth handling and transportation

Paperboard is a thick, paper-based material made from cellulose fibers derived from wood pulp or recycled paper. It is known for its rigidity, foldability, and smooth surface.

Paperboard is commonly used for custom packaging because it is lightweight, easy to customize, and excellent for printing, lamination, and specialty coatings. Types of paperboard include folding boxboard, chipboard, kraft board, laminated board, solid bleached board (SBB), solid unbleached board (SUB), linerboard, and containerboard.

Paperboard is used for:

High-quality branding and printing

Premium finishing and coatings

Precise and secure product packaging

Enhanced visual appeal and functionality

Protection during shipping and handling

Card stock, also referred to as cover stock or pasteboard, is thicker than standard paper but thinner than paperboard. It features a smooth or textured surface and is available in matte, glossy, or metallic finishes.

In the packaging industry, card stock is valued for its flexibility, durability, and excellent print performance. It is commonly used for lightweight product packaging, promotional boxes, and inserts.

Card stock offers:

A solid yet pliable surface for printing

Lightweight protection for retail products

Easy folding and shaping

Smooth shipping and handling

Professional and clean presentation

Corrugated fibreboard, often called corrugated cardboard, consists of a fluted corrugated sheet sandwiched between two flat linerboards. The fluted layer provides cushioning and strength, while the linerboards offer a smooth printable surface.

Corrugated material is widely used for shipping and protective packaging due to its durability, lightweight structure, and sustainability.

Key benefits of corrugated fibreboard include:

Shock absorption during transit

High stacking strength for storage

Custom inserts and dividers for added protection

Excellent printability for branding

Cost-effective and recyclable packaging

Kraft paper is produced using the kraft pulping process, resulting in a strong, tear-resistant material with high tensile strength. It is known for its natural appearance and eco-friendly properties.

In the packaging industry, kraft paper is highly valued for its durability and sustainability. It is commonly used for bags, wrapping paper, mailers, shipping boxes, and eco-friendly packaging solutions.

Kraft paper provides:

Strong resistance against damage

Protection from dust and scratches

Natural and rustic branding appeal

Recyclable and biodegradable packaging

Reliable performance during shipping

Rigid material is known for its exceptional stiffness, strength, and structural integrity. It maintains its shape and provides maximum protection for delicate and high-value products.

Rigid packaging is commonly used for luxury and premium products where presentation and protection are equally important.

Rigid material offers:

Superior protection against external pressure

Premium and high-end packaging appearance

Secure storage for fragile products

Long-lasting durability

Enhanced product presentation

Cover materials are used to enhance the visual appeal, functionality, and branding of custom boxes. At Apex Box Packaging, we offer a wide variety of cover paper options to suit different packaging needs.

Common cover materials include:

Solid colour paper

Custom printed paper

Foil paper

Laminated paper

Embossed paper

Matte paper

Gloss paper

You can customize your packaging using any of these cover materials to meet your product and branding requirements.

Solid colour paper features uniform coloration throughout the sheet and is available in a wide range of shades.

It is commonly used for branding-focused packaging where bold and consistent colours are required to enhance brand recognition and shelf appeal.

Custom printed paper allows logos, graphics, patterns, and text to be printed directly onto the surface.

This cover material is ideal for personalized packaging and brand promotion, offering complete design flexibility and a professional finish.

Foil paper features a metallic foil layer applied to the surface, available in gold, silver, and other metallic shades.

It is widely used for luxury and premium packaging to create an elegant and eye-catching appearance.

Laminated paper is coated with a thin plastic film that can be matte, gloss, or satin.

This cover material enhances durability, water resistance, and surface protection while providing a smooth and refined finish.

Embossed paper features raised textures created through patterned dies.

It is commonly used for luxury packaging to add depth, texture, and a premium tactile experience.

Matte paper has a non-glossy finish that minimizes glare and reflections.

It is preferred for sophisticated packaging designs, accurate colour reproduction, and resistance to fingerprints and smudges.

Gloss paper features a shiny, reflective coating that enhances colour vibrancy and image sharpness.

It is ideal for high-impact packaging designs, offering moisture resistance and superior print quality.

Paper-based packaging materials such as cardboard, paperboard, card stock, corrugated fibreboard, kraft paper, and rigid materials play a vital role in the packaging industry.

These materials are valued for their:

Strength and durability

Lightweight nature

Stackable storage

Environmental sustainability

Cost-efficient shipping and transportation

Choosing the right material enhances both product protection and brand presentation while supporting eco-friendly practices.

Custom box materials are durable due to high-quality paper fibers that provide flexibility, tensile strength, and resistance to wear. Thickness and density add rigidity while maintaining lightweight properties.

Structural features such as folds, flaps, and creases distribute weight evenly, increasing overall packaging strength.

Custom box materials protect products during shipping through their sturdy construction, folding strength, and shock-absorbing properties.

Corrugated fluting, custom inserts, and protective layers prevent damage from bumps, drops, and rough handling during transportation.

Enhanced product protection during shipping

Strong brand recognition through high-quality printing

Improved customer satisfaction and perceived value

Reduced shipping costs with optimized materials

Eco-friendly solutions that minimize waste

Purpose and functionality

Material type and strength

Customization options

Cost-effectiveness

Branding and visual appeal

Environmental impact

Storage and organization

Shipping and transportation needs

Yes, most custom packaging materials used by Apex Box Packaging are recyclable, biodegradable, and environmentally responsible.

Yes, custom box materials are designed to withstand pressure, shipping stress, and external damage while keeping products secure.

Yes, paper-based custom boxes are preferred due to their strength, lightweight nature, recyclability, and environmental benefits.

Yes, custom box materials can be tailored for industries such as retail, e-commerce, food, cosmetics, electronics, pharmaceuticals, apparel, stationery, and toys.

Packaging cost depends on material quality, durability, customization options, eco-friendly features, and order quantity.

Yes, custom box materials support high-quality printing for logos, brand colours, graphics, and product information to enhance brand visibility.